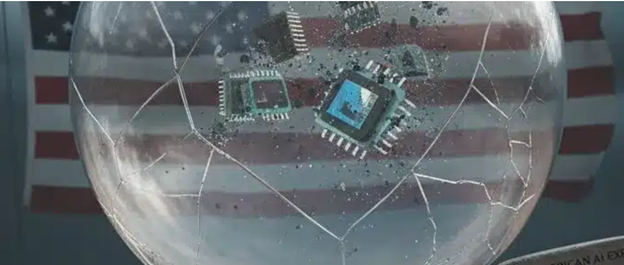

Above photo: This artwork is a symbolic commentary on the state of American technological innovation and its dependency on rare earth minerals. Substack.

Export controls over rare earths and other materials show that reality has the final say.

When Washington declared an economic war on China’s technology ascent, it assumed it held the upper hand. Tariffs, export bans, entity lists and chip sanctions were meant to isolate Beijing, choke its access to critical inputs, strangle its technological development and protect American primacy. Yet with remarkable precision, Beijing has now demonstrated that the United States is the one more deeply entangled in – and dependent upon – China’s command of critical material supply chains.

China’s latest round of export controls on lithium batteries, graphite anode materials, and rare earth technologies amounts to the most significant intensification yet in the global race for material sovereignty. The measures are framed in terms of “national security,” and necessities to meet China’s obligations to not accelerate arms proliferation. At the same time, the strategic timing and scope make clear their geopolitical intent: to again expose the material vulnerability of a country that has worked tirelessly to encircle, contain and repress China, but which itself cannot easily reconstitute its own productive base.

The New Controls: Materials that Power the Modern World

The new Chinese restrictions announced on 9 October 2025 extend beyond commodities to include the technological processes required to make them useful. This is a deft and also an important expansion of reach from mere resource control to technological chokepoint management.

In terms of graphite anode materials and lithium batteries, China will now require export permits for synthetic graphite and natural graphite materials used in the production of lithium-ion battery anodes. The restrictions also cover advanced production processes, including granulation, continuous graphitisation, and liquid-phase coating. These are all key technologies that determine battery performance and durability. These technologies are essential for electric vehicles (EVs), consumer electronics and grid-scale energy storage systems. China currently accounts for over 90% of the world’s graphite anode production and dominates every stage of the lithium battery value chain.

As for rare earth-related technologies China has added a sweeping range of rare earth technologies to its export control list, including those involved in mining, smelting, separation, magnetic material manufacturing, and secondary resource recycling. These underpin the manufacture of permanent magnets used in wind turbines, electric motors, guided missile systems, fighter jets, satellite components and semiconductors. China refines nearly 90% of global rare earth oxides and produces the vast majority of neodymium-iron-boron (NdFeB) magnets used in high-performance electronics.

Together, these measures strike at the heart of the clean energy, defence, and semiconductor industries. In other words, the very sectors the U.S. has spent billions trying to re-shore through the Inflation Reduction Act and CHIPS Act under the Biden Administration, and which are central to the Trump Administration’s vision for America’s techno-military future. (The focus on clean energy has been dropped.)

The Immediate Impact: A U.S. Industrial System Built on Imported Foundations

The material and temporal constraints are impossible to downplay. The U.S. simply does not have the capacity, time or industrial ecosystem to replace what China supplies within a period of time that will be meaningful.

According to the Pentagon, over 78% of U.S. military systems rely on materials sourced directly or indirectly from China. Rare earths are used in everything from jet engines and precision-guided munitions to radar systems and nuclear submarine components. A disruption in Chinese supply chains would delay weapons production and maintenance schedules. The U.S. has some rare earth deposits but lacks refining and metallurgical expertise; ironically, these were offshored to China decades ago. Rebuilding domestic refining capacity could take 5–10 years and cost billions, even before environmental approvals and workforce training are considered. Against this backdrop, China’s export restrictions can be seen to be a massive boost to world peace.

While U.S. policymakers focus on lithography and chip design, the less glamorous but critical material inputs – rare earths, gallium, germanium and graphite – remain overwhelmingly Chinese. Rare earth magnets are essential in chip fabrication equipment and data centre cooling systems. Restrictions on graphite and high-purity processing technologies will squeeze the semiconductor value chain from the bottom up, affecting everything from consumer electronics to AI compute clusters. This has wide-ranging implications. Without the rapid expansion of AI capital development in 2025 (data centres and the like), the US GDP growth for the first half of 2025 would have been, according to some estimates, no more than 0.1%. Put another way, the American economy writ large is flaccid at best, and AI-related capex is keeping its head above water. Disruptions to the input supply chains needed by the AI sector will jeopardise the sector’s expansion; it will also increase costs due to supply side disruptions. The impacts of China’s restrictions are double-barrelled: they go to the resources needed for augmenting the US electricity supply sector on the one hand, while also creating bottleneck risks in the supply of semiconductors. The Wall Street AI bubble may well be exposed to the sharp needle of Chinese export restrictions.

The EV revolution in the U.S., if indeed one could even call it that, depends on a Chinese battery ecosystem that dominates both upstream materials and midstream processing. China processes two-thirds of the world’s lithium and over 90% of the world’s graphite. U.S. automakers have only recently begun investing in local cathode and anode production, but the know-how and equipment still come largely from Chinese firms. Supply disruptions will increase EV costs, reduce availability, and slow decarbonisation timelines.

In short, America’s green and digital transitions are built on Chinese foundations. Now those foundations are shifting, or perhaps worse, those foundations have simply been removed.

A Problem of Time, Capital and Capability

It is one thing to announce subsidies and grand industrial acts; it is another to rebuild entire production ecosystems hollowed out over 40 years of offshoring. The United States faces a threefold constraint: time, resources, and knowledge. In terms of time developing new mining, refining, and magnet manufacturing capacity is not a matter of quarters or even years; it’s a decade-long process. Environmental permitting alone can stall U.S. projects for years, while Chinese firms are already vertically integrated and continuously upgrading. As for material resources, even if the U.S. opened every known domestic deposit tomorrow, it still lacks the refining and separation facilities to make those materials usable. Mining without refining simply shifts the bottleneck. Lastly, the US faces knowledge and equipment constraints. China’s near-monopoly on rare earth processing equipment and graphite treatment technology means that even friendly suppliers – Australia, Canada or Brazil – depend on Chinese machinery and expertise. The U.S. does not have the skilled labour force or capital goods base to replicate these processes quickly.

The result is a structural dilemma. No amount of rhetoric or subsidy can compress industrial time. The U.S. can print money, but it cannot print metallurgists, engineers, or processing plants. As I argued in May, the US can keep its dollars; China has the dysprosium.

Strategic Blowback: Isolation by Design

Ironically, the U.S. has engineered its own isolation. By attempting to exclude China from global technology networks, Washington has incentivised Beijing to constrain the very supply chains the U.S. once took for granted. China, for its part, has pursued a measured escalation strategy; first restricting gallium and germanium exports in 2023, now broadening to rare earth technologies and graphite. Each move demonstrates both restraint and capability: China can choose when, where, and how to tighten the tap.

For the U.S., this is more than an economic inconvenience. It is a geostrategic humiliation. The self-declared arsenal of democracy is now dependent on the industrial capacity of the very nation it sought to cripple.

Europe and the Global South: Opportunity Amid Disruption

While Washington scrambles, others are positioning to profit from the fracture.

The European Union, long caught between U.S. pressure and Chinese supply dependence, can use this crisis to accelerate its own reindustrialisation, if – and, frankly, this is a very big if – it had the policy, political and institutional dexterity, acumen and wherewithal to do so. It could, for instance, boost investment in refining and magnet production. Projects in Sweden, Finland and France are already developing local rare earth refining capacity. China’s tightening gives the Europeans both urgency and bargaining power. The EU actually gains some leverage over Washington. The U.S. may be forced to look to Europe for certain high-tech inputs and cooperation. Brussels could trade that support for concessions on subsidies, tariffs and technology sharing. At the same time, Europe can pursue a more pragmatic approach – diversifying without decoupling – preserving access to Chinese supply while building local resilience.

In essence, Europe can extract strategic rents from U.S. vulnerability while reinforcing its own industrial base under the banner of “strategic autonomy.” Whether the present leadership in Brussels is open to these possibilities is another story altogether, however.

For resource-rich states in the Global South, this moment is potentially transformative. Countries like Indonesia, Chile, Brazil and the DRC are already leveraging resource nationalism to demand local processing and value addition. China’s industrial footprint provides them an alternative to U.S.-led models – offering investment, technology and infrastructure without geopolitical lectures. The U.S., arriving late with conditional offers and limited capital, cannot easily compete.

For once, the Global South holds some real cards. Some countries of the global south control the inputs of the 21st century economy. They can sell to China, partner with China and / or Europe, or engage in some strategic hedging.

The Inevitable Reckoning

The United States is discovering that it cannot “sanction” the world while remaining sanction-proof itself. Its industrial capacity, the envy of the globe in days gone by, has been hollowed out by decades of financialisation, offshoring and short-termism.

China’s new controls have revealed the underlying asymmetry of the global economy: one side makes things; the other makes narratives. The real economy of thermodynamics and materials trumps the economy of fictitious capital and simulacra. The U.S. may still dominate finance, media and military power projection, but without access to the materials that make advanced technologies possible, these advantages are increasingly performative.

Washington tried to isolate Beijing. In doing so, it isolated itself. Presidents Trump and Xi are slated to meet on the sidelines of APEC in South Korea later in October. That will be a very interesting conversation, indeed.